Aiming for factor4 of molding factories

Causes of dimensional inaccuracy in plastic molding and countermeasures.

2023.03.17

There are various types of defects in resin molded products, but deformations such as warping and twisting may not be able to perform their own functions if they deviate from the tolerances of the design dimensions, and they may have an adverse effect on subsequent assembly processes. and may lead to product failure.

Why does such deformation cause dimensional defects? In this article, we will introduce the causes and countermeasures for the deterioration of the dimensional accuracy of molded products.

Why do part size problems occur?

First, let's look at the causes of dimensional defects after molding.

Material property

Resin has the property of expanding when heated and melted, and shrinking when cooled and solidified. It is necessary to design the mold considering the shrinkage rate and determine various conditions before molding.

Resins can be broadly divided into crystalline resins and non-crystalline resins, but the shrinkage rate differs greatly for each. Crystalline resins solidify (crystallize) with their molecules arranged in an orderly manner, while non-crystalline resins have the property of solidifying (not crystallizing) with their molecules disjointed.

Crystalline resins have high chemical resistance and fatigue resistance, but since they have a high degree of shrinkage during molding, products that require precise dimensional accuracy require more consideration from the design stage. In this way, it may be difficult to achieve dimensional accuracy due to the characteristics of the resin material itself.

uneven cooling

In crystalline resins, there is a property that the degree of crystallinity decreases as the cooling rate increases. For example, the entire molded product may not be cooled uniformly depending on the thick and thin parts of the molded product, the shape of the mold and the position of the water pipe. Uneven cooling causes differences in the crystallinity of each part of the molded product, resulting in dimensional defects such as warpage and distortion.

residual stress

Particular attention should be paid to residual stress. In general, it is called "residual stress", which refers to the state in which force remains inside an object when external force is applied to it, or when processing, heat treatment, cooling, etc. are performed.

In injection molding of resin, when the resin is injected into the mold, a large pressure is applied along with the change in temperature, and this remains in the molded product. As time passes and temperature changes, the residual stress is gradually released, causing deformation, warping, and distortion of the molded product.

Cause of residual stress

The causes of residual stress are complex and are thought to be caused by the accumulation of multiple factors.

1) Uneven external force

Many resin molded products have complicated shapes, and depending on the difference in thickness between parts and the position of the gate, there are parts that are susceptible to pressure during injection and parts that are not.

Other causes, such as undercuts that bite into the mold when the part is removed from the mold, or improper placement of ejector pins, can cause uneven external forces on the part. may be affected.

2) uneven cooling

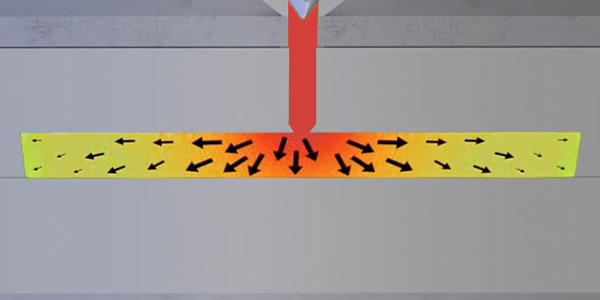

The cooling rate also varies depending on the shape of the molded product and the position and shape of the cooling water pipes in the mold.

In normal molds, the water pipes for cooling are drilled and the cooling water path is configured linearly, so there will inevitably be differences in cooling depending on the location. Also, the cooling rate differs between thick and thin sections.

3) Uneven shrinkage due to material characteristics

Resins mixed with reinforcing fibers are sometimes used to increase strength and durability. When reinforcing fibers are blended, the molding shrinkage rate generally decreases, but since the fibers tend to be oriented in the direction of flow, anisotropy is created, and shrinkage rates differ depending on the orientation, and as a result, stress may remain. I have.

In this way, residual stress is thought to be caused by the uneven external force applied to the molded product, the cooling rate inside the molded product, and the difference in contraction rate.

How to improve the dimensional accuracy of molded products

"Improve the dimensional accuracy of the molded product" does not mean improving the dimensional accuracy beyond what was aimed at when designing the mold, but maintaining the shape after molding as it is (not deforming), stabilizing the dimensions. Talk to you. In order to suppress deformation after molding, there are roughly two methods: reducing the stress generated during molding and releasing residual stress.

First, let's start with "annealing" (= "annealing"), a method of releasing residual stress that has long been used in the heat treatment of iron products.

Annealing

There is a method of adding heat treatment to reduce residual stress in resin molded products after molding. This process is called annealing.

In the case of crystalline resin, it is placed at a temperature 10 to 30°C higher than the actual operating temperature for a certain period of time, and then slowly cooled to increase the degree of crystallinity. This makes it possible to increase heat-resistant resistance and rigidity and prevent deformation.

Also, with non-crystalline resin, placing it at a temperature slightly lower than the deflection temperature under load for a certain period of time allows the molecules in the resin to move, allowing the residual stress to be released. By slowly cooling it in that state, deformation will not occur.

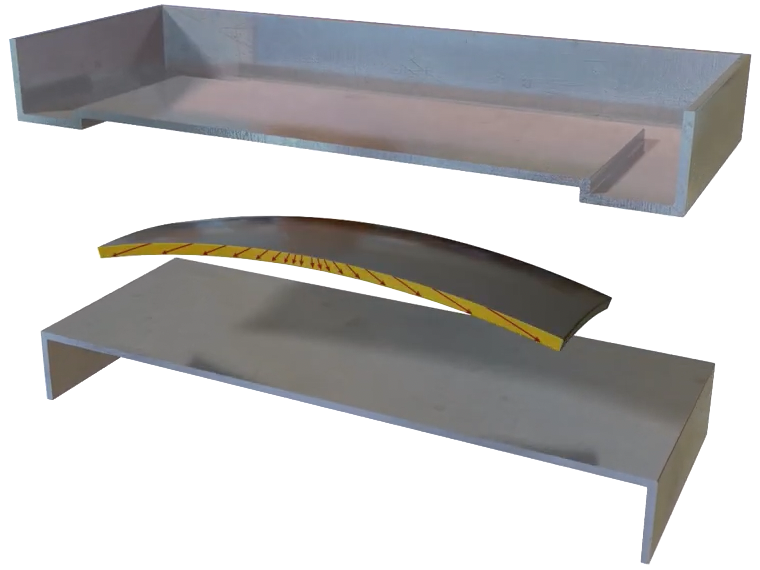

You may think that preparing a dedicated annealing furnace is a large and difficult task, but Matsui's Tray dryer PO has been used by many customers as an annealing furnace for many years. It does not take up much space, and the introduction cost can be reduced.

Multi-zone temperature control

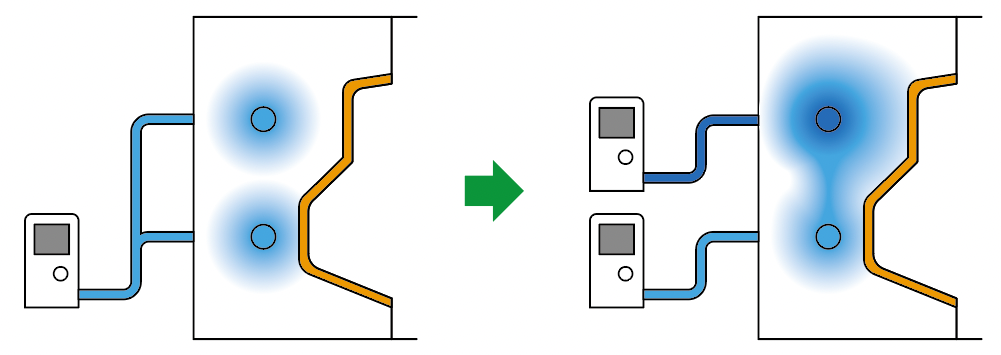

Multi-zone temperature control is effective when there is a difference in the cooling rate due to the shape of the molded product.

In normal molding, one mold temperature controller is used to cool the mold. Therefore, in a three-dimensional molded product, there is a difference in the distance between the molding surface and the cooling water pipe for each part, and there are parts that cool easily and parts that do not cool easily. To address this problem, multi-zone temperature control using multiple Mold Temperature Controller can set different temperatures for different parts, reducing variations in cooling speeds for different parts.

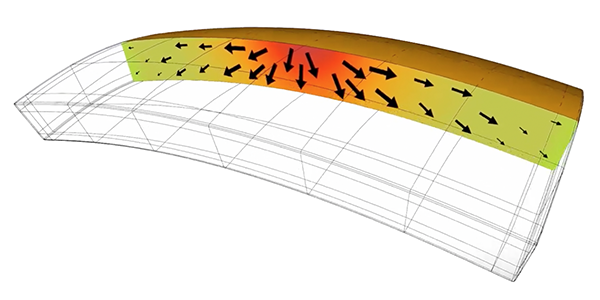

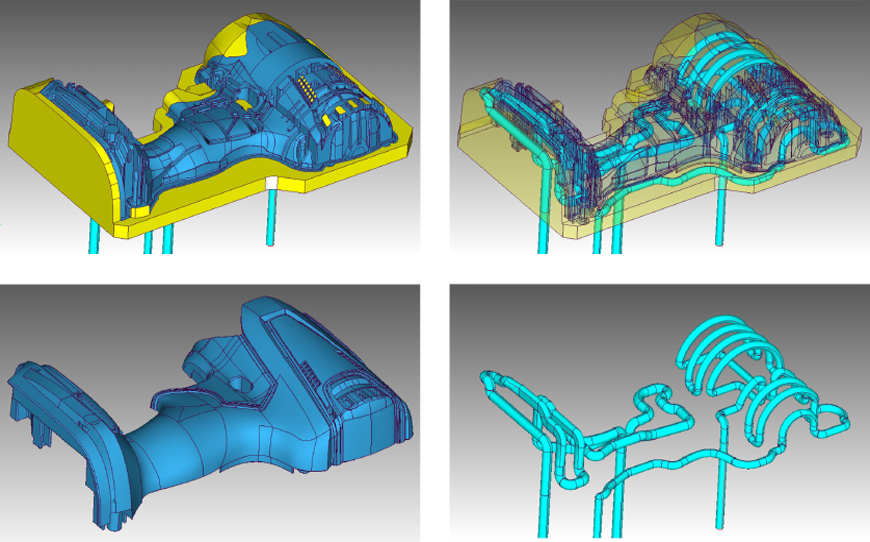

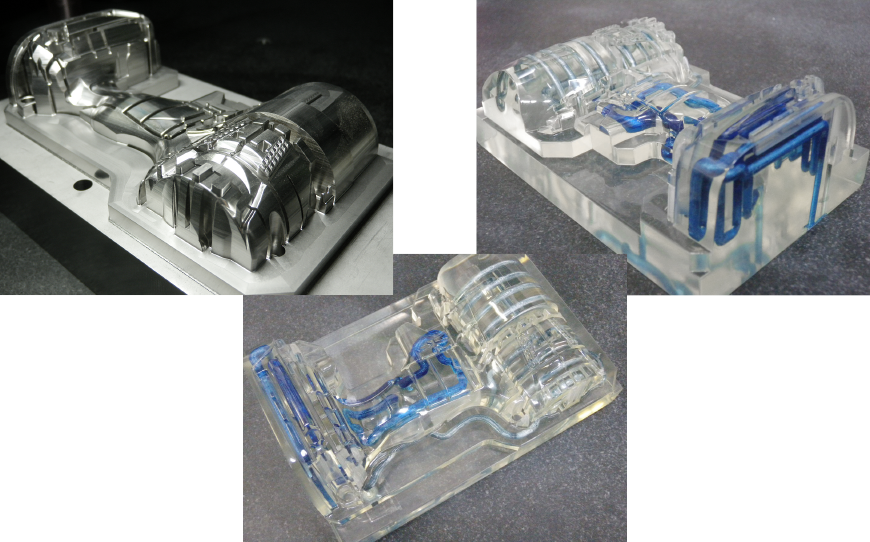

3D water pipe

Conventional mold water pipes have been made by drilling holes, connecting them in straight lines, and filling in the unnecessary parts, so only linear paths were possible. However, by using a 3D metal printer, cooling water pipes can be routed freely along the molding surface even in three-dimensional molded products. This allows uniform cooling even for molded products with complex shapes. ⇒ 3D Water Pipe Mold Nesting

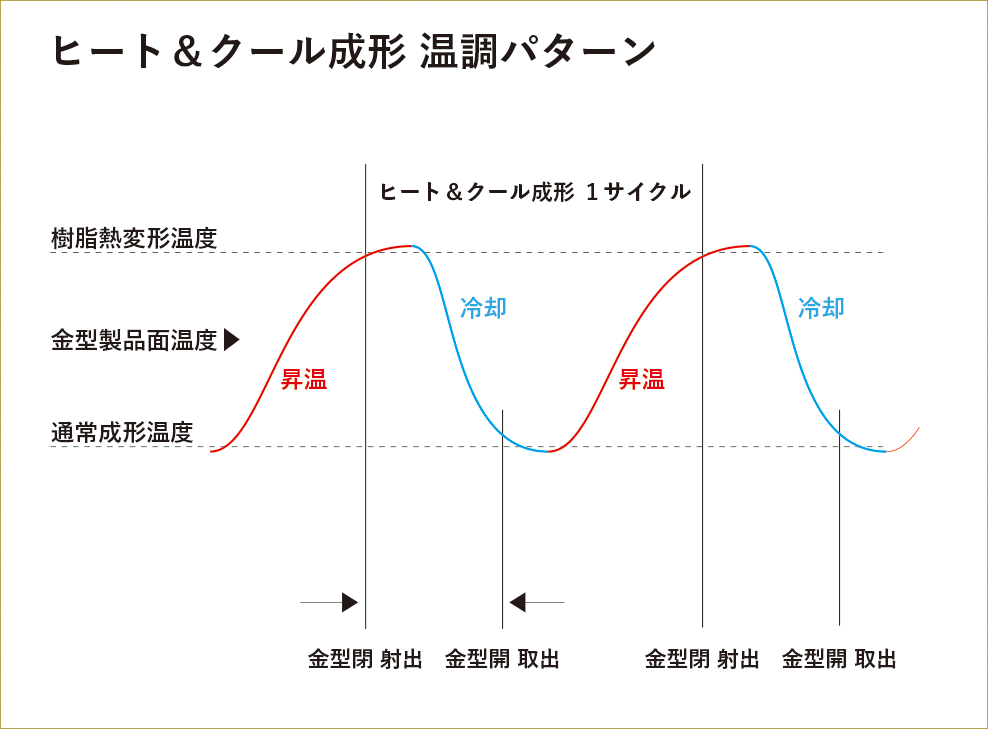

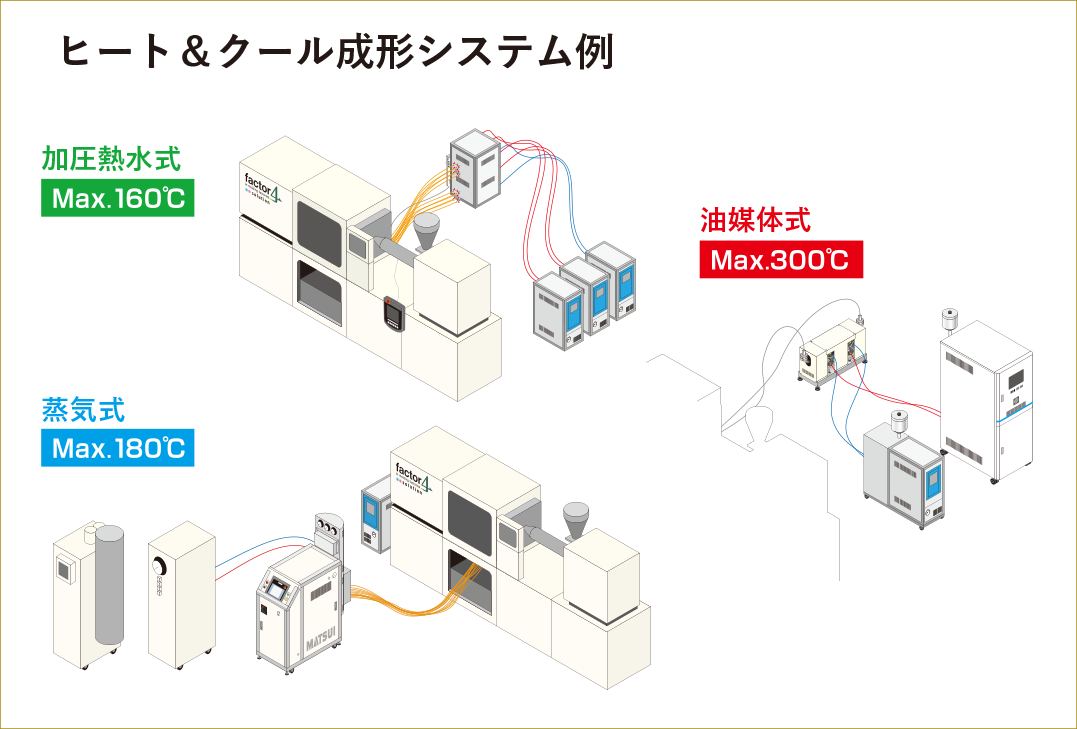

heat & cool molding

This is a molding technology in which the mold temperature is raised and then rapidly cooled when resin is filled into the mold, and this process is repeated. Not only is it effective in improving the appearance quality by making weld lines invisible, but it also improves the fluidity when injecting the resin, making it easier to fill molded products that are difficult for resin to flow, such as thin or thick parts. Increased fluidity = Less force is required to fill, reducing the effects of residual stress and improving dimensional accuracy. ⇒Heat & Cool Molding

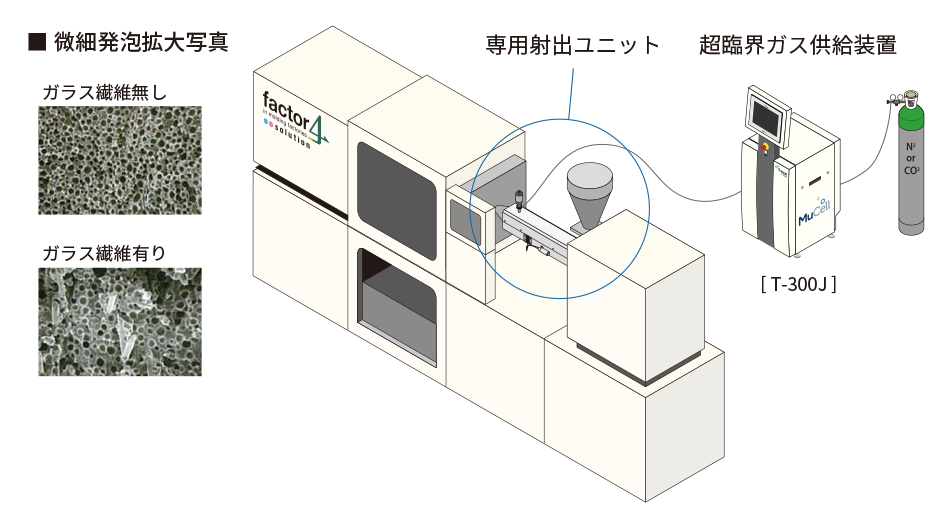

Foam molding

This is a molding method in which a foaming agent is mixed into the resin, or a supercritical fluid is dissolved in the resin as a foaming agent, and foaming occurs inside the molded product by reducing the pressure after filling the mold. By generating bubbles inside the resin, pressure is applied evenly, so no stress remains in one direction, and deformation defects such as warping and sink marks are suppressed.

⇒ MuCell® Microcellular Foam Molding System

Summary

Dimensional problems of resin molded products are greatly affected by resin characteristics, cooling method, and residual stress. These can be dealt with by knowing the properties of the resin and using technology. Improving the dimensional accuracy of the molded product will also show the technical capabilities of the molding factory, contributing to increased value.

MATSUI, we prepare proposals for improving the dimensional accuracy of molded products and support the introduction of new equipment and technology. Please feel free to contact us.