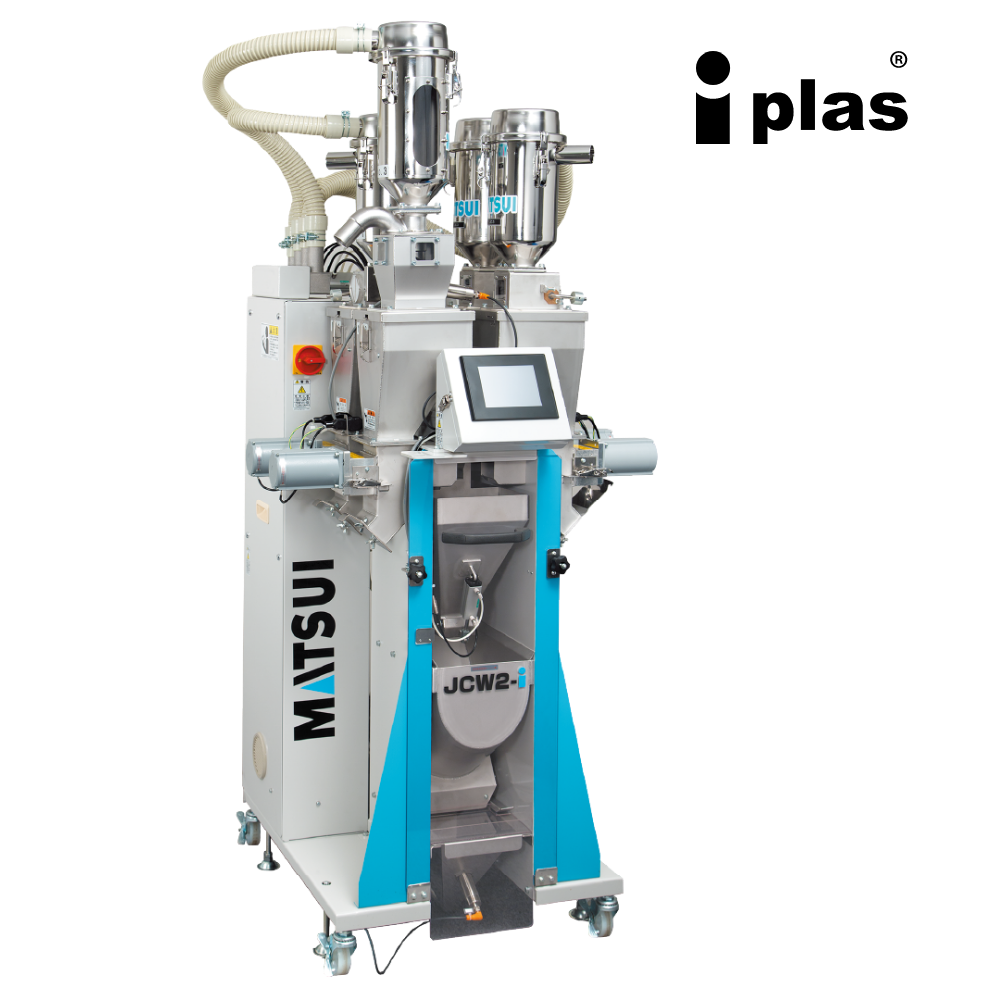

Features of JCGB2

1. The unique valve shape and mixing ratio correction function enable highly accurate mixing!

Measurement accuracy is improved by limiting the amount of material fed at one time to less than 15g. In addition, the feed amount (target value) of each material is corrected and adjusted according to the actual feed amount, achieving ideal, uniform, high-quality molding.

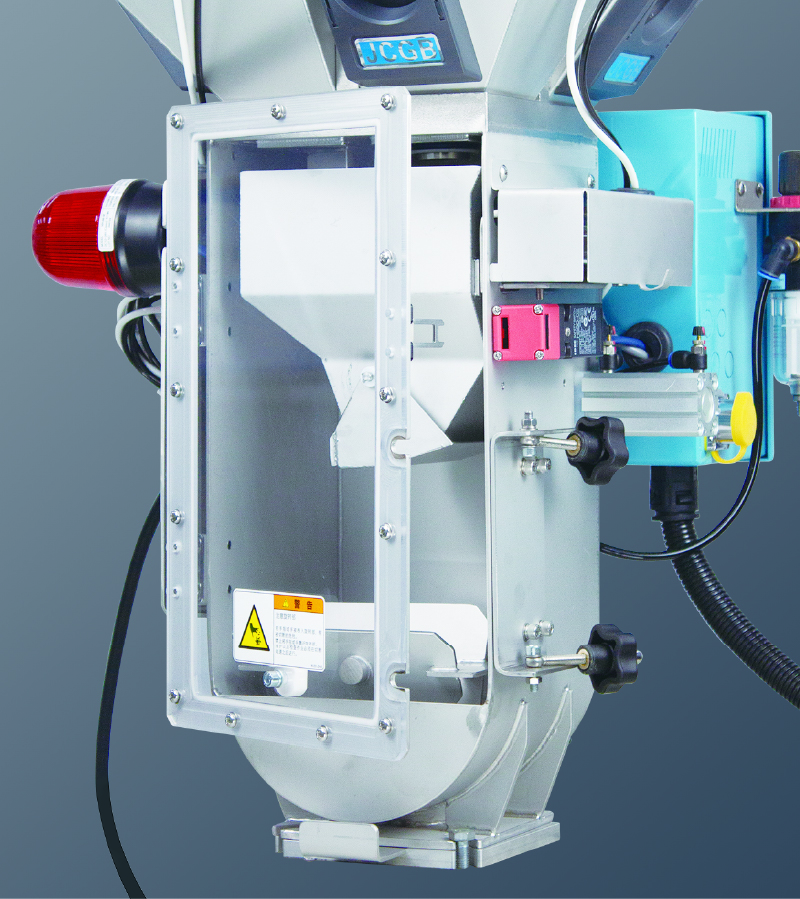

It uses a uniquely shaped inclined hole valve that reduces jamming.

The valve moves up and down to cut out the material, reducing the amount fed at one time.

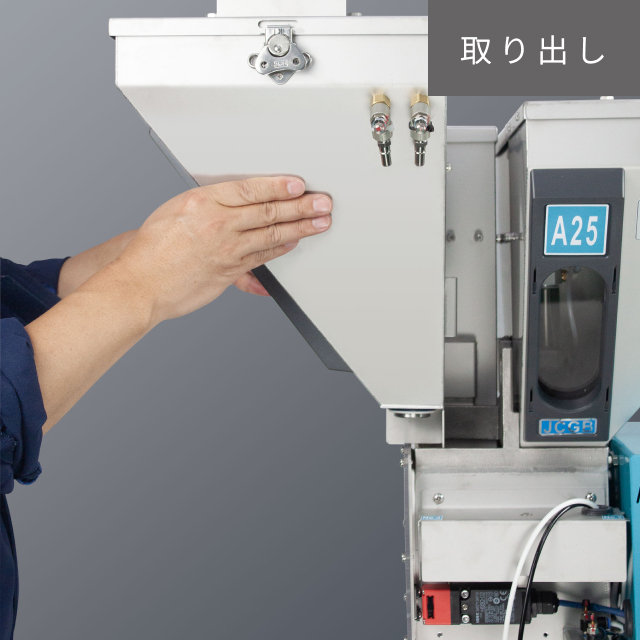

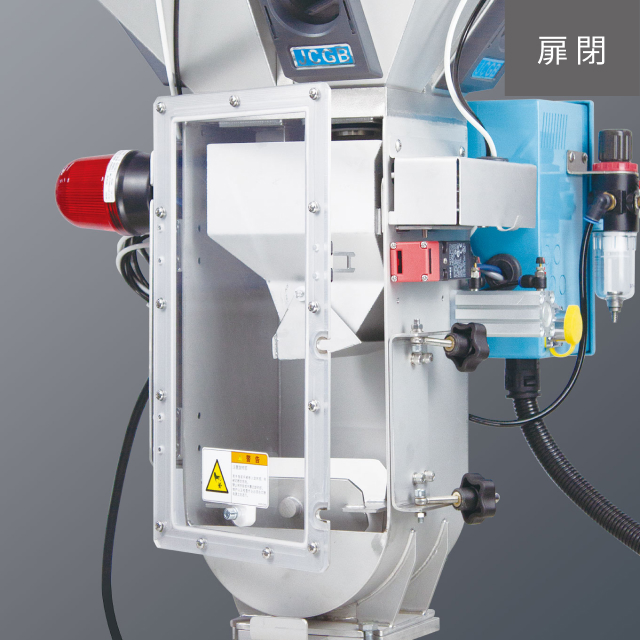

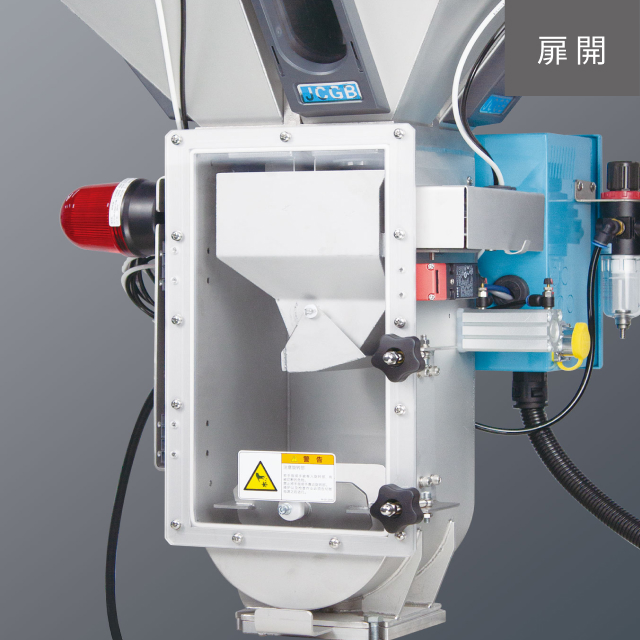

2. No special tools are required, making maintenance easy!

The main units, such as the material hopper and Measuring hopper, can be easily removed for maintenance without the need for special tools. The simple structure also contributes to reducing cleaning time when changing materials.

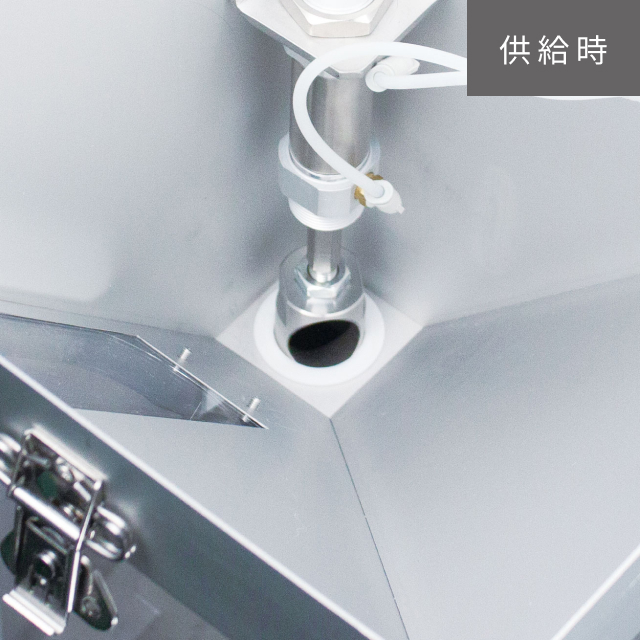

💡By storing the material supply valve inside the hopper, the material hopper can be removed smoothly!

💡Taking into consideration handling on the molding machine, the front door is designed to be able to open and close!

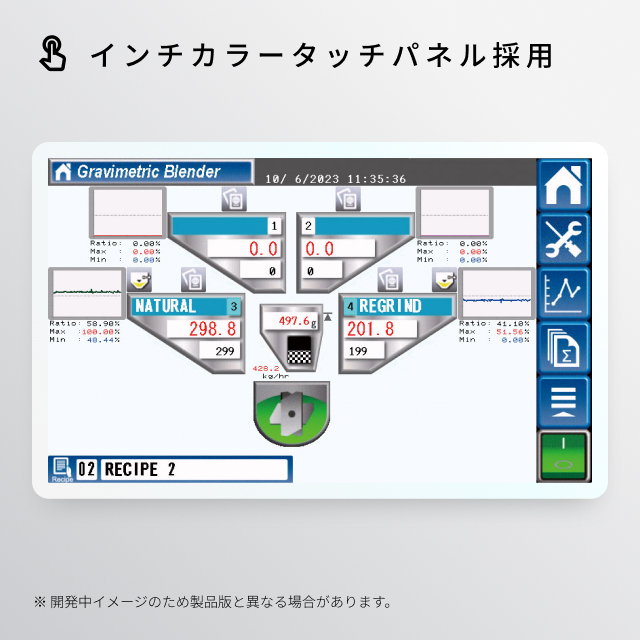

3. An operation panel packed with convenient functions!

Here we will introduce some of the features.

💡Displays performance data for each batch as a trend graph!

💡Can store weight results, drop, cumulative value, weighing time, and alarm history data for 500 batches!

💡By importing data to a PC via USB, traceability (history management) of molded products is possible!

Product related videos

This is a product video of an older model with a similar product overview. Please watch it for reference.