Features

1. The double structure design eliminates color unevenness caused by static electricity and differences in specific gravity!

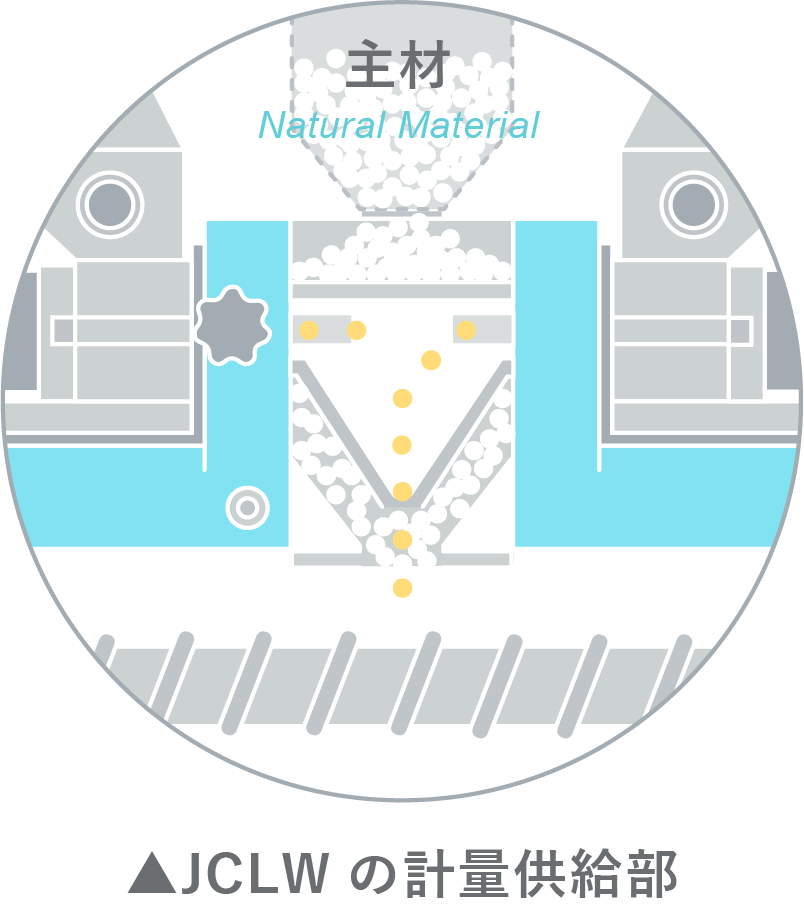

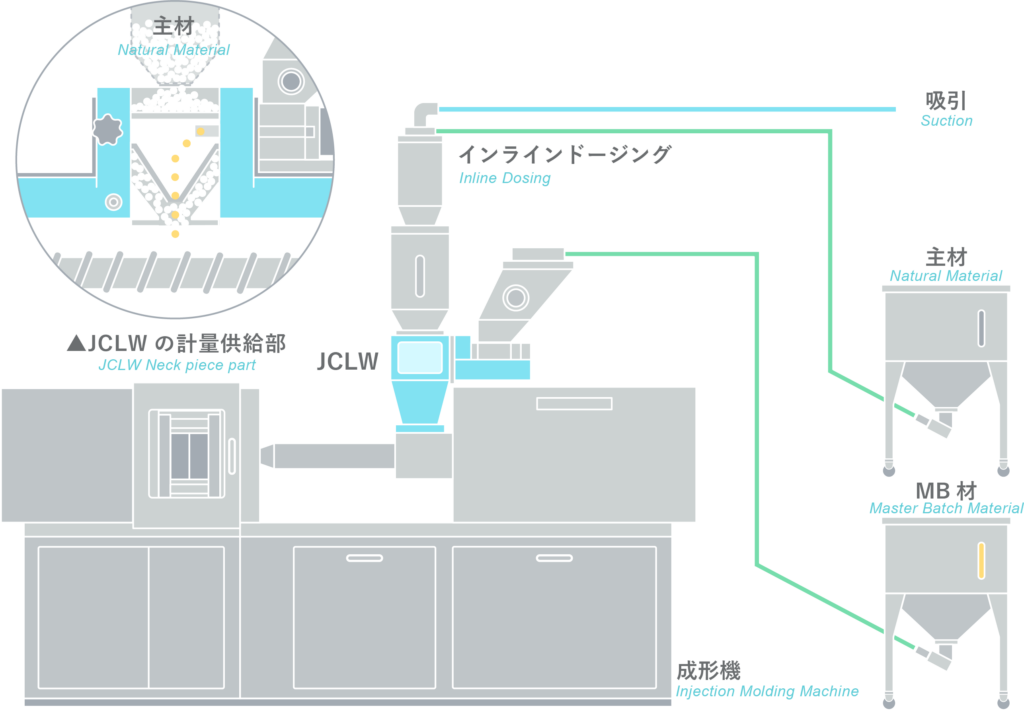

In JCLW, Virgin material and MB material are charged separately and mixed just before the molding machine's Loading port charge hopper. Virgin material flows through the outside of the double structure and is supplied by gravity. Meanwhile, the MB material passes through the inside of the double structure and is supplied from the side. This makes it possible to prevent supply problems such as MB material sticking to charge hopper due to static electricity during mixing and only Virgin material being supplied, compared to conventional charge hoppers.

Loss-in method (production reduction method)

JCLW is a mass-based loss-in method that manages how many grams should be reduced from the current weight. Compared to volumetric methods, it is less affected by the shape of the material, so it is possible to always measure a consistent amount.

If material is transported during calculation, the system will switch to volumetric operation in locked operation mode.

2. By optimizing the amount of MB material added, annual costs can be reduced by 10 to 20%!

*Cost reduction effects vary depending on molding conditions.

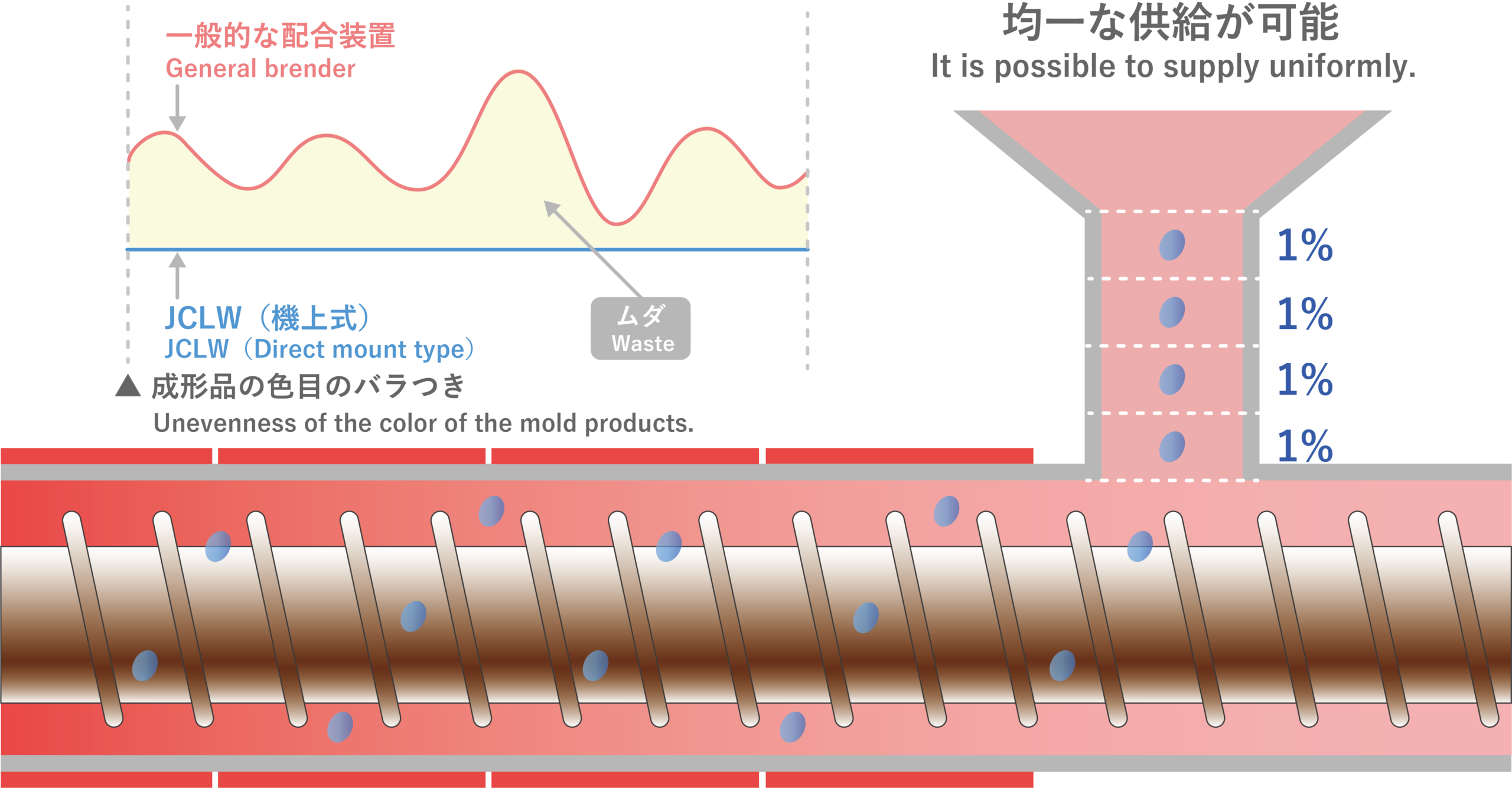

The amount of MB material used is generally small, at 1-5% of Virgin material. However, because it is an expensive material, optimizing the amount used is essential. In this way, proper management of MB material also leads to cost management, such as cost reduction. JCLW uses a dosing cylinder in the supply section, which achieves a more stable supply than a screw feeder. With a screw feeder, the screw groove causes a pulsating discharge, but since the dosing cylinder does not have a screw Blade, it suppresses pulsation and allows for stable and accurate material supply.

The graph above shows the change in supply volume of blending equipment.

In the case of a typical mixing device (orange line), the setting value must be set slightly higher, at 1.1% or 1.2%, to ensure that the lower limit of MB material is 1%.

However, in the case of JCLW (light blue line), the amount of additive is stable, so it is possible to save MB material.

3. On-board installation solves secondary transportation problems!

A typical floor-mounted blending device requires a large installation area and secondary transport. On the other hand, JCLW is installed between charge hopper and the molding machine, and performs calculations and blending on the machine, eliminating the need for secondary transport. Therefore, separation of materials due to material transport does not occur.

4. It's easy to change ingredients frequently!

Especially in production sites with a wide variety of products in small quantities, the issue of how quickly and reliably material changes can be completed is an issue. In such sites where frequent material changes are required, the JCLW with its simple structure is useful.

The material hopper can be easily attached and detached by simply turning the grip.

You can quickly change colors by opening the sliding shutter at the bottom of the hopper!

The cylinder can be removed with one touch, making it easy for anyone to work on.

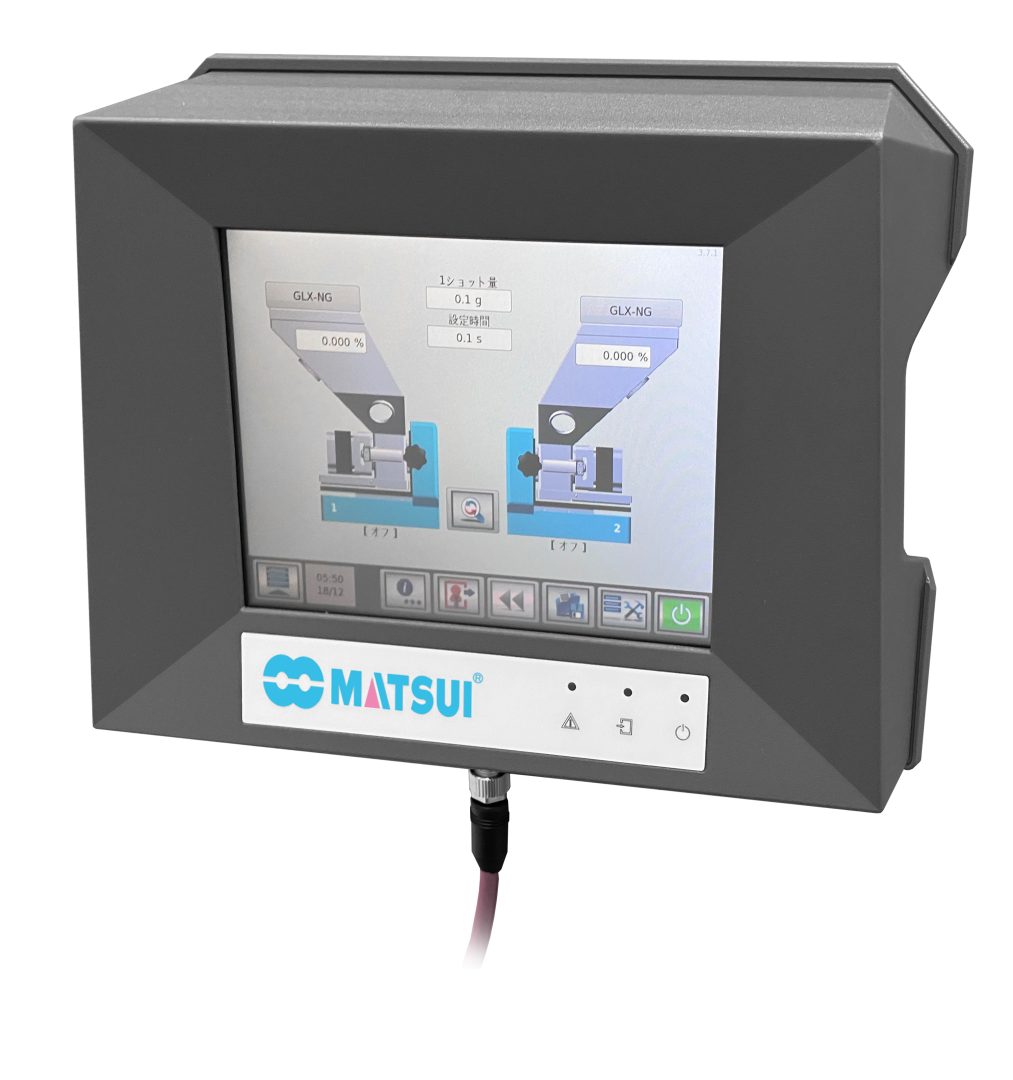

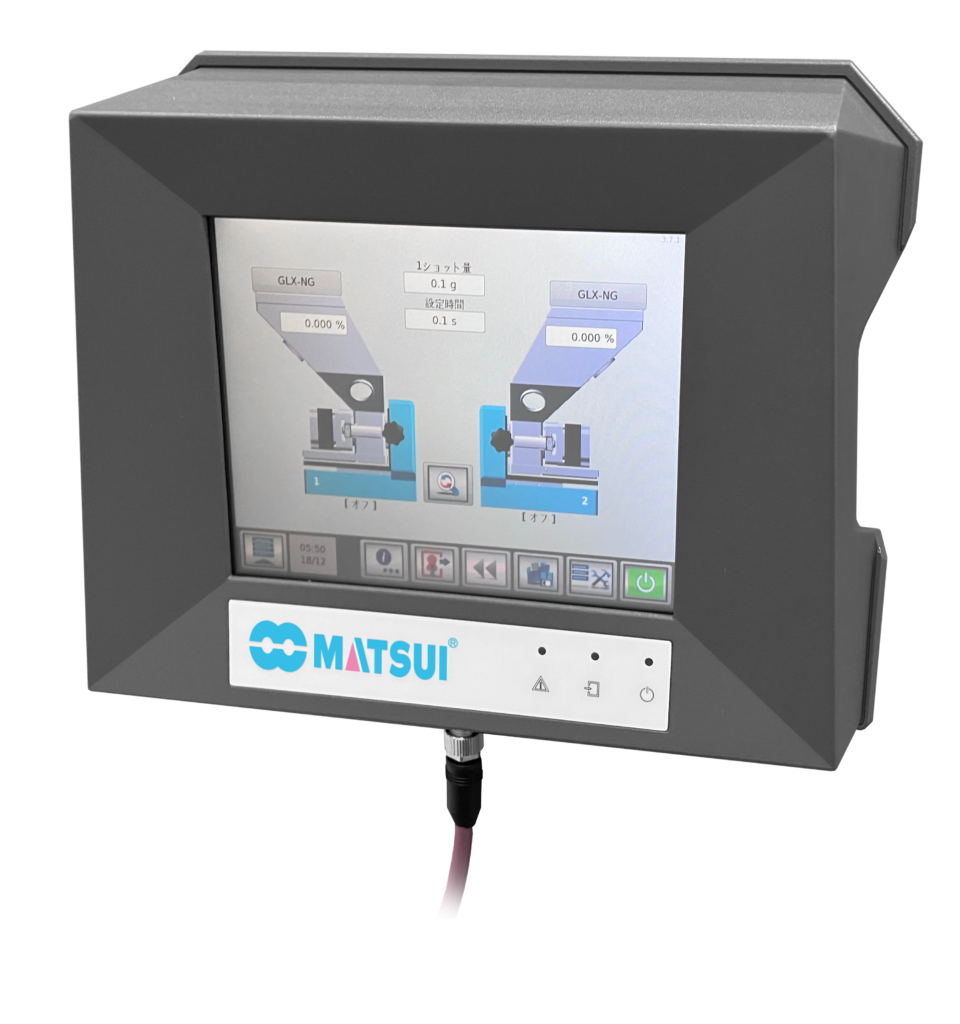

5. Touch screen controller for stress-free molding!

Equipped with an 8-inch color touch panel that is highly visible and allows intuitive operation. The operation unit is separate, and the magnetic mounting structure and connection cable (standard length 3m) allow for highly flexible handling. The controller combines operability and flexibility, contributing to the creation of a stress-free work environment.

6. We also manage the traceability of all shots!

The optional dedicated software allows you to manage data for every shot.

It can be connected to the company's internal network using a wired LAN. It contributes to improving work efficiency by storing 500 combination settings for each Blenders and changing conditions from a PC.