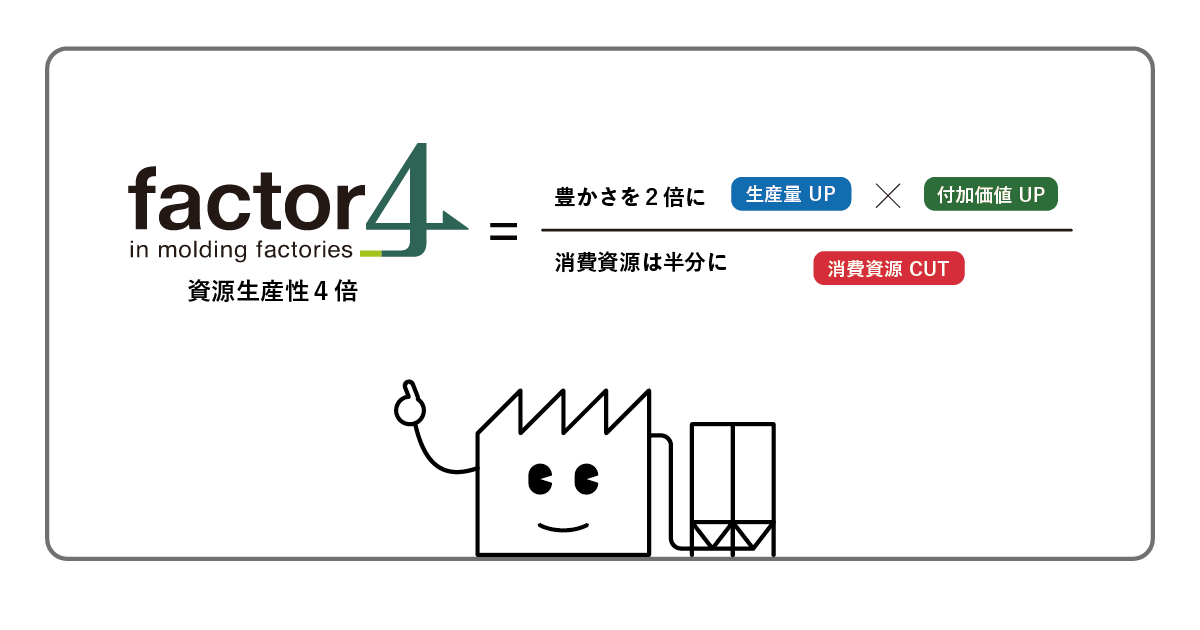

Aiming for factor4 of molding factories

"Increase production volume" Reduce defects & stable production, shorten molding cycle

2022.01.06

Even if you say "production volume up", I think that everyone is producing as much as possible in the usual way, so you may think "What should I do from there !?" ..

Simply put, a molding machine is operating continuously, with a 100% operating rate resulting in the highest production volume, but in reality, there is a need for "setup time" when the molding machine stops to change molds or materials each time a different molded product is made. This time can be said to be the time necessary for production.

Therefore, here, I would like to think about "increasing production volume" by the following four approaches.

1. Reduction of molding defects

2. Maintaining the initial state

3. Shorten set up times

4.Reduced Reduction in cycle time

1. Reduction of molding defects

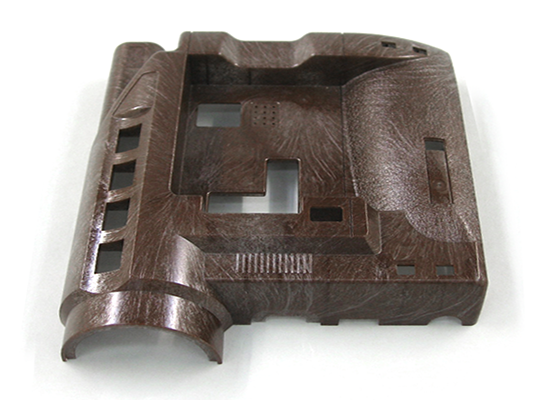

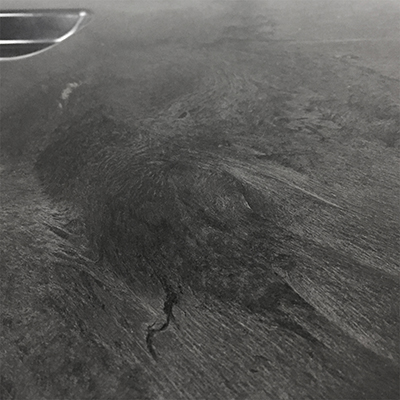

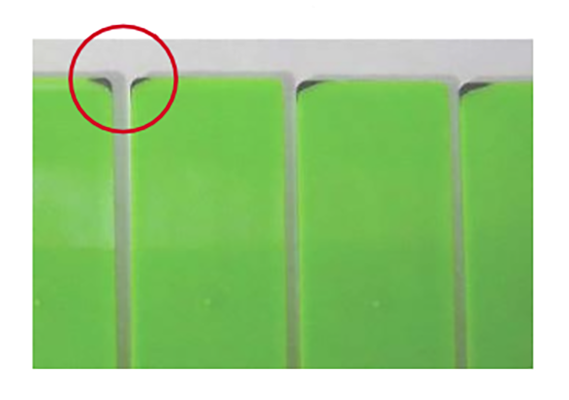

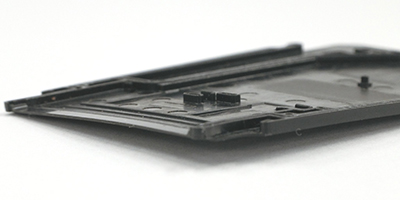

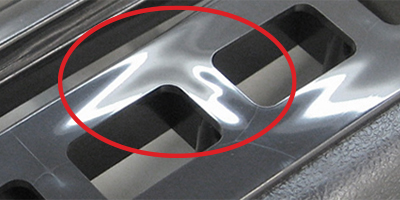

There are various symptoms and causes of molding defects. Phenomena include stringing, poor mold release, short shots, gas burns, burrs, flow marks, silver streaks, weld lines, sink marks, warpage, voids, yellowing, deformation ... Causes include mold shape (design) and These include molding conditions, resin selection and dryness, changes in environment (temperature / humidity) and cooling efficiency, and generation of contamination and gas.

Since there are so many defects and defects, it is necessary to solve each one individually. Not all of them are uniform, but since we have been working with everyone involved in resin molding for a long time, we have been working with everyone involved in resin molding for a long time, so we have analyzed the resin flow of molds, properly dried the resin, removed gas, took measures against contamination, weldless molding equipment & We have a wide range of solutions that can solve problems and issues at your factory, from know-how to monitoring the environment and molding status using IoT, and water quality management for the entire factory.

2. Maintaining the initial state (preventing equipment malfunction)

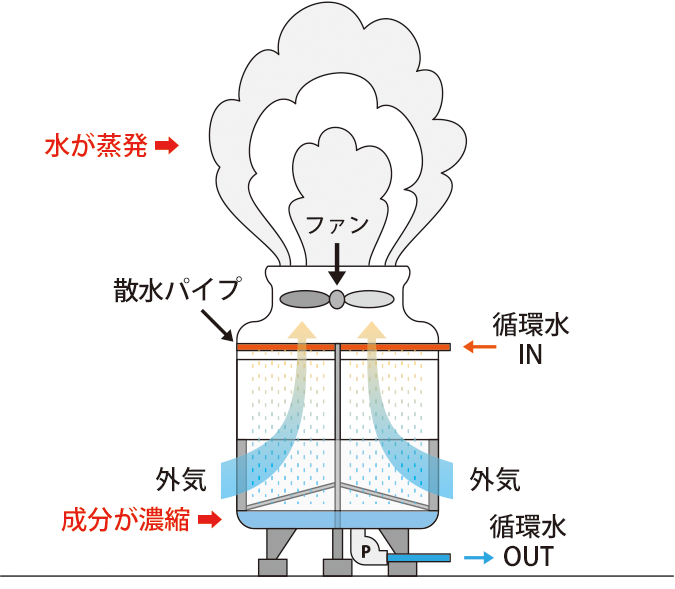

Although good products were obtained without problems for a while after the adjustment was completed and mass production started, molding defects gradually increased. In order to obtain good products, the conditions of the molding machine and the set temperature of the mold temperature control were changed. Have you ever experienced an increase in cycle time as a result? For one thing, it may be due to seasonal temperature changes, but what is often overlooked is the quality of the cooling water.

Even in factory where the company recognizes the importance of maintaining water quality, most people other than those in charge of management rarely have a chance to see factory circulating water. Also, even if you look at the water in the water tank or cooling tower, you probably won't pay much attention to it unless it's obviously dirty. In fact, even if the water looks clean, it can lead to equipment problems and reduced cooling efficiency.

The causes of the decrease in cooling efficiency are dust and plant spores that have entered from the outside, bacteria and rust generated in the cooling system, and lime that is a combination of calcium and magnesium contained in the water. By adhering to the inner wall, it becomes impossible to sufficiently Replacement heat with the temperature-controlled object. If it gets clogged, it may lead to equipment malfunction or Breakdown.

Ideally, we should be able to introduce a system that takes into account the maintenance of water quality when starting up a factory or establishing a new line. We will propose the optimal method, method, and step-up from various solutions such as decomposing and recovering scale, water pipe cleaning, ionization, anti-rust agents, bactericides, and water quality modifiers.

3. Shorten set up times

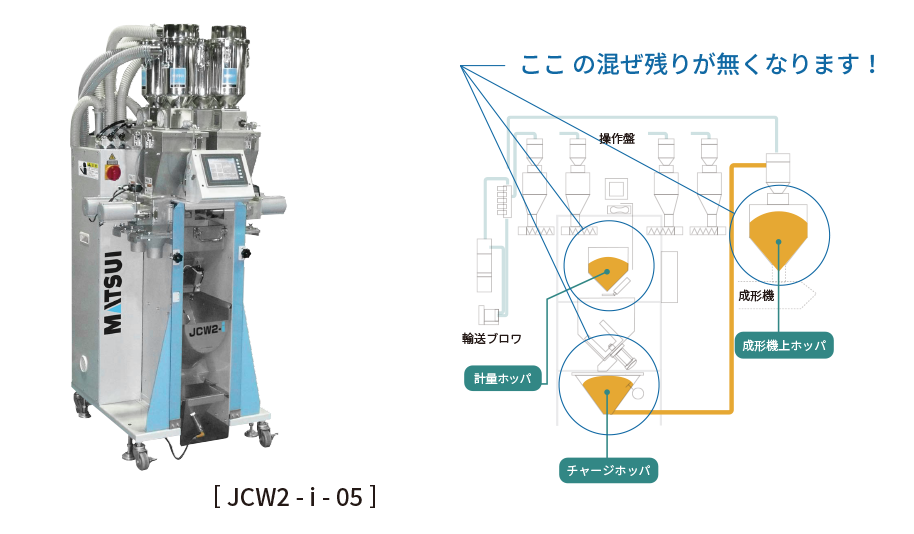

Material change and mold change will take time and effort in setup. When changing materials, it is necessary to completely replace the materials of many parts such as transportation routes, compounding equipment, collector the molding machine, cylinders, screws, and cleaning so that the previous materials do not remain and mix. ..

In the order of the process, for example, the next material is pre-dried, the Conveying line is switched easily and surely, the Blend material is used up exactly according to the production situation, the retention is eliminated and the material is replaced in a short time, etc. That's why there is a way to save time.

Click here for details ⇒ JCW2-i Gravimetric Blender with intelligence function

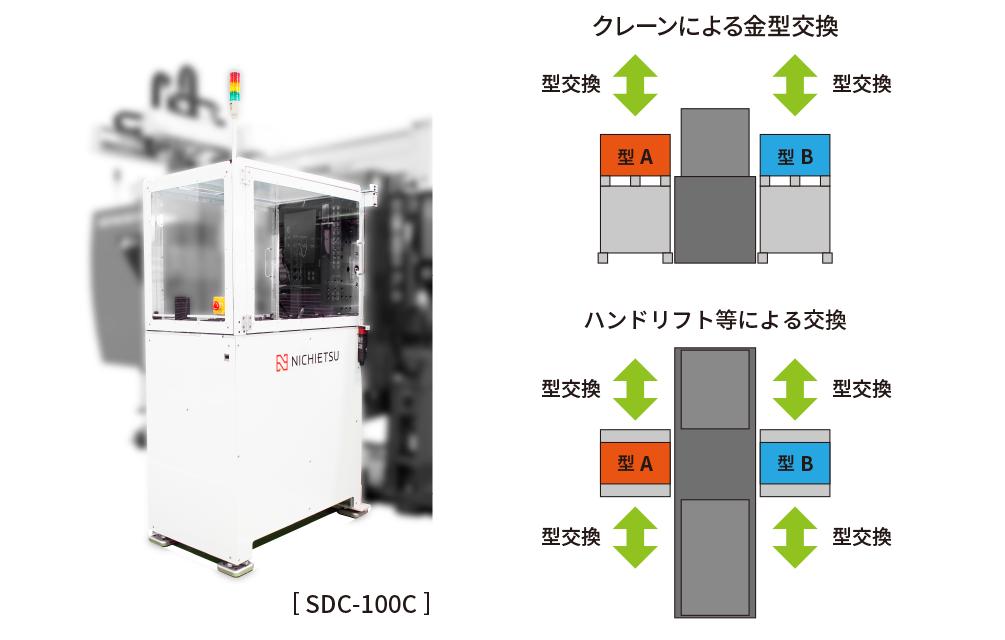

In mold Replacement, wait for the temperature of the mold to drop, manually remove it from the molding machine, place the next mold, connect the pipes, wait until the temperature rises, and then start adjusting the molding conditions. Performing these operations with the molding machine stopped is called "inner setup", and making the next preparation while molding is called outer setup. How far can this outer setup be advanced? , It is a point to shorten the setup time.

If there is a mechanism that allows the next mold to stand by nearby, prepares the preliminary temperature, and can be easily replaced, it will be possible to set up efficiently in a short time.

Click here for details ⇒ Mold Changer changer SDC

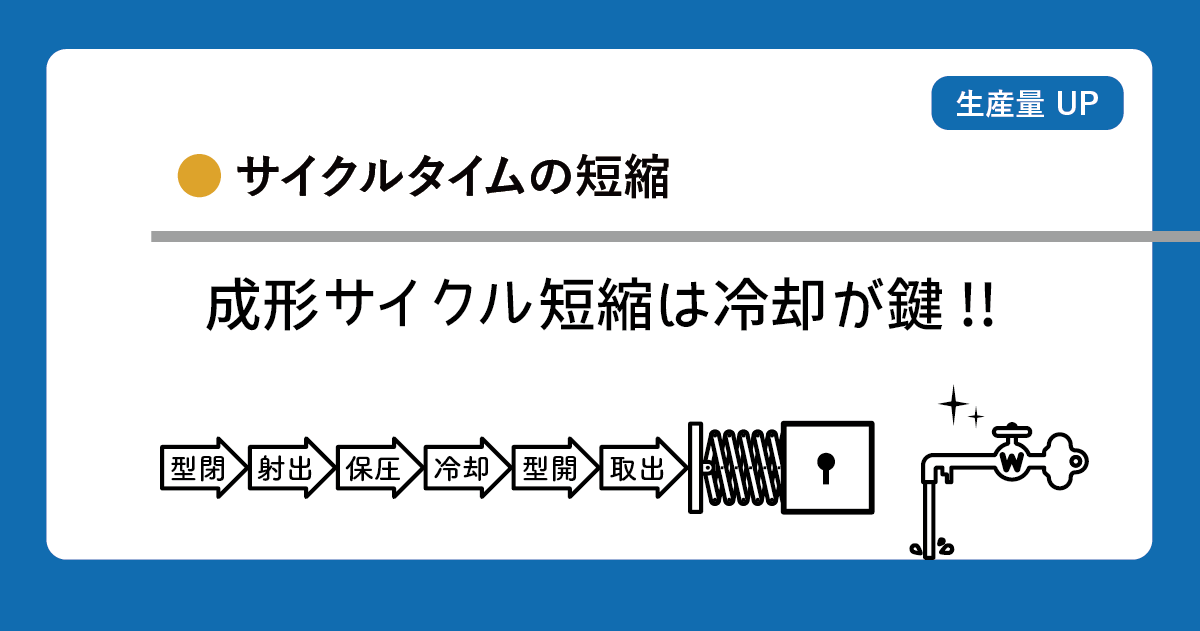

4. Reduction in cycle time

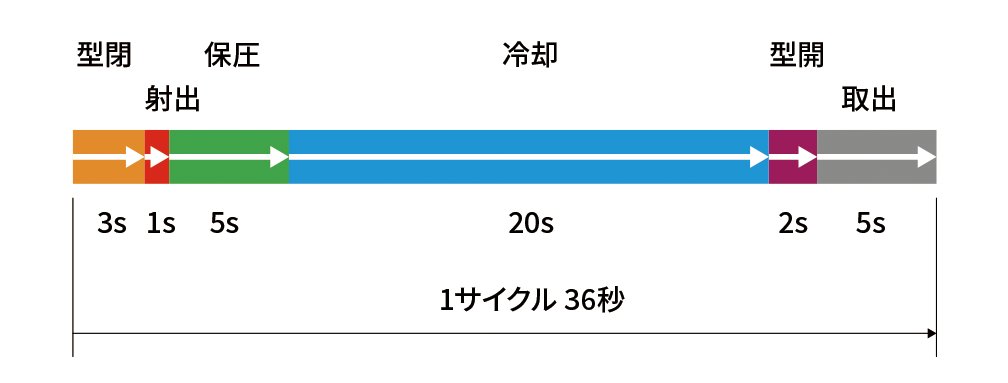

If you show the time share of each process of the cycle time in molding in the figure, it will look like this, for example.

The key is how to shorten the cooling process, which takes the longest time. There are two main ways to do this: one is to reduce the occurrence of defects when shortening the cooling time, and the other is to increase the cooling efficiency itself. Matsui has a range of items to reduce defects such as stringiness, warping, and sink marks, as well as solutions to review water pipes to match the shape of the molded product and maintain heat exchange efficiency for efficient cooling.

Specific methods / methods and solution items will be introduced in 12 columns by solution theme.

Global Solution Promotion Department Yasuhiko Iijima