Aiming for factor4 of molding factories

Surface quality improvement of injection molded products.

2023.04.04

What comes to mind when you hear the term surface quality of molded products? Problems and issues such as low yield due to poor molding, difficult surface treatment before painting and plating, various conditions have been changed, but it is difficult to improve further, and the required quality is increasing year by year. I think it varies.

In previous columns, we have introduced measures to improve defects, color unevenness, and sink marks that appear on the surface of molded products. Defects that are difficult to improve include weld lines, which are marks like line scratches that appear at the part where the resin merges in the molded product. In addition, in order to improve the strength and reduce the weight of molded products, technologies such as adding fillers and foaming have been introduced. has become

In this column, we will introduce the details of each defect, the improvement method (molding method) that achieves a high surface quality that could not be achieved with normal molding, and the mechanism for improving the defect.

Molding defects appearing on the surface

First, let's list some types of defects that can be improved by the molding methods introduced in this column.

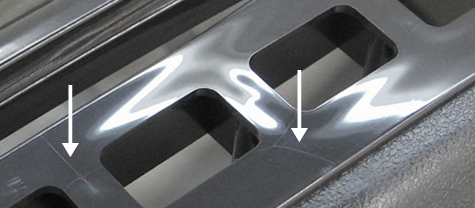

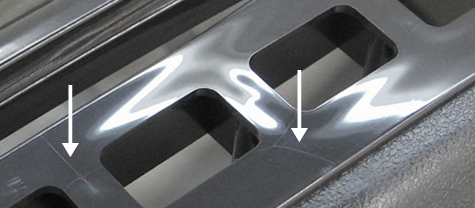

weld line

A "weld line" is a thin line mark that appears in the part where the resin merges in the molded product. This phenomenon occurs when resin is injected into a mold, for example, in a molded product with an opening, it branches off at the position of the hole and merges again, or resin injected from multiple locations collides with each other at a multi-point gate. This is due to matching movements. This phenomenon always occurs in molded products with openings or multi-point gates, although the degree of appearance varies.

If strength is required, the weld line will be a weak point. From the viewpoint of surface quality, there is no problem if it can be hidden with paint. may be

Poor transfer

Molded products with a leather-like embossed pattern or mirror-like gloss are often used for the purpose of producing a high-class feeling with molded products such as automobile interior parts and home appliances. These designs are realized by transferring the designs on the mold surface. Improper transfer means that the fine patterns, embossed textures, and mirror surface conditions envisioned when designing and manufacturing the mold are not properly transferred to the molded product, and the intended expression is not achieved.

If the embossed pattern is not transferred correctly, the edges will not be reproduced, and the molded product will have an overall shine. In addition, if the mirror surface is poorly transferred, the degree of gloss is low, the condition of the molded surface is not uniform, and the reflection (reflection) is uneven.

Filler expression

When molding with resin mixed with filler (glass fiber, carbon fiber, etc.) to improve the strength of the molded product, the filler appears on the surface of the molded product, making it look rough and not smooth. There is a thing

Even if the filler is exposed, there is no problem with the shape or strength, so there are many cases where it is used as it is as a mechanical part or a part that is not visible from the outside, but it is treated as a defective part as an external part.

Orientation in metallic molding

Until now, metallic paint and plating have been commonly used to express metal-like textures in plastic products. However, in recent years, from the viewpoint of health hazards and environmental problems, efforts are being made to reduce or even eliminate the painting process. For this reason, metallic molding that achieves a metal-like texture without painting is attracting attention, and many companies involved in molding and resin material manufacturers are conducting research.

Metallic molding is a molding method in which fine aluminum flakes are mixed with resin and molded to give a metallic luster without the need for painting or plating. However, at parts such as the openings, ribs, bosses, etc. of the molded product, where the resin collides with each other and the flakes are aligned in the same direction, the flakes are dented even though there is no superficial deformation. or the striped pattern may look uneven or wavy. This "orientation" is regarded as defective in terms of surface quality in metallic molding.

How to solve defects that appear on the surface of molded products

The four defects introduced so far are examples that are difficult to improve simply by changing materials or changing molding conditions. Even with these defects, many customers continue molding with a low yield in order to meet the quality requirements of the delivery destination. If the molding temperature is set higher, it can be improved to some extent, but the higher the temperature, the longer it takes to cool down, resulting in a longer cycle time and lower production efficiency.

Therefore, we propose "Heat & Cool Molding" as a means to solve the problems and issues of defects that appear on the surface of these molded products, and as a way to dramatically improve molding quality.

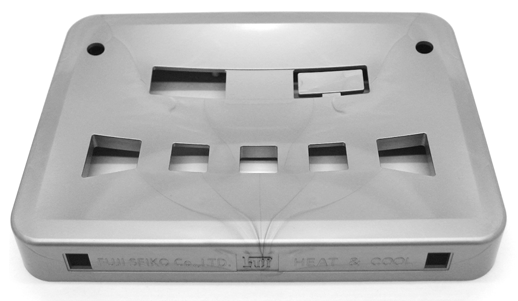

What is heat & cool molding?

"Heat & Cool Molding" is a technology suitable for improving the surface quality of molded products. It is a molding method that increases the fluidity of the resin by raising the molding surface of the mold to a temperature range close to the glass transition point of the resin and maintaining a high temperature during injection. Increasing the fluidity of the resin helps to solve various issues that have led to defects. In addition, rapid cooling reduces the extension of cooling time, and uniform cooling reduces deformation after molding, which also leads to Improve Dimensional Precision.

* When heat & cool molding is introduced, the cycle time tends to be longer than in normal molding, but in some cases, such as thick molded products, the rapid cooling effect leads to shortened cycle time.

Appearance defects improved by heat and cool molding

From here, we will explain the mechanism by which "Heat & Cool Molding" works to improve the appearance defects mentioned above.

Weld line improvement

"Heat & Cool Molding" is also known as "weldless molding" because it was originally developed as a molding method to eliminate weld lines. By raising the temperature of the molding surface of the mold to a temperature range close to the glass transition point of the resin and injecting it in that state, the fluidity of the resin is increased, making it possible to achieve a surface quality that makes weld lines invisible to the naked eye.

*Actually, the physical movement of the resin colliding around the opening of the molded product does not change, and it does not fuse at that position, so the weld line exists internally. However, the result is a clean, uniform surface that is indistinguishable.

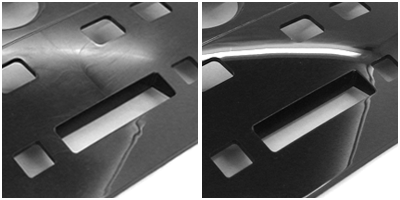

Improving poor transfer

If the molded product is molded with a mold that has been textured on the molding surface and the transfer is defective, the surface that should have a matte finish will have a worn-out luster. This is because the injected resin hits the mold surface and the temperature drops, and solidification begins before the resin flows into the deep part of the pattern, resulting in a smoothed edge.

With "Heat & Cool Molding", the injected resin reaches every corner of the deepest parts, so the texture and fine patterns engraved on the molded surface are faithfully transferred to the molded surface. As a result, the desired design is accurately reproduced on the surface of the molded product. In addition, with mirror finish, the surface is transferred as it is, so the mirror gloss that was previously created by secondary processing such as painting can be reproduced in an unpainted state.

In everyday life, the term piano black* refers to the jet-black, glossy surfaces of molded products such as the center console and instrument panel of a car, the outer frame of a car navigation system, and the outer frame of a television in home appliances.

*Piano black: Meaning of black with brilliance and depth like that of a piano case

Improved filler appearance

The "exposed" filler refers to the fact that additives such as glass fiber, which are mixed with the resin to give strength, heat-resistant, and various resistances, are visible on the surface of the molded product.

In normal molding, when molten resin containing filler is injected into the mold, the fountain flow (*1) movement of the resin causes the filler to pop out from the flow front (*2) and press against the mold wall. Because it hardens, it remains visible on the surface.

If this is molded using "heat and cool molding," very good surface quality can be obtained. In terms of mechanism, the temperature of the mold wall is high, the resin around the pressed filler is still in a loose state, and the resin covers the filler due to the mold pressure, resulting in high-quality surface quality with no exposed filler.

*1 Fountain flow: When the resin is injected into the mold, it cools when it hits the surface of the mold and loses its fluidity.

*2 Flow front: The tip of the resin that is injected into the mold and flows into it.

Improved orientation

The flakes used in metallic molding are flakes rather than spheres, so they align along the flow of the resin so that they can be reflected diffusely and look glittery. Even if the surface of the molded product is in good condition, this "orientation" is visible, so the color may appear uneven, and parts with ribs or bosses on the back may appear to be recessed.

This orientation is actually one of the difficult issues to improve even with "Heat & Cool Molding", but we were able to improve it by combining it with another technology. Because this is a jointly developed technology with a collaborating company, I cannot go into details, but by using a high-temperature type heat & cool device that uses oil as a medium and a special mold, and by using a mechanism to control the injection and move the resin inside the mold, we were able to eliminate the orientation by changing the direction of the aligned flakes.

Important points when introducing heat & cool molding

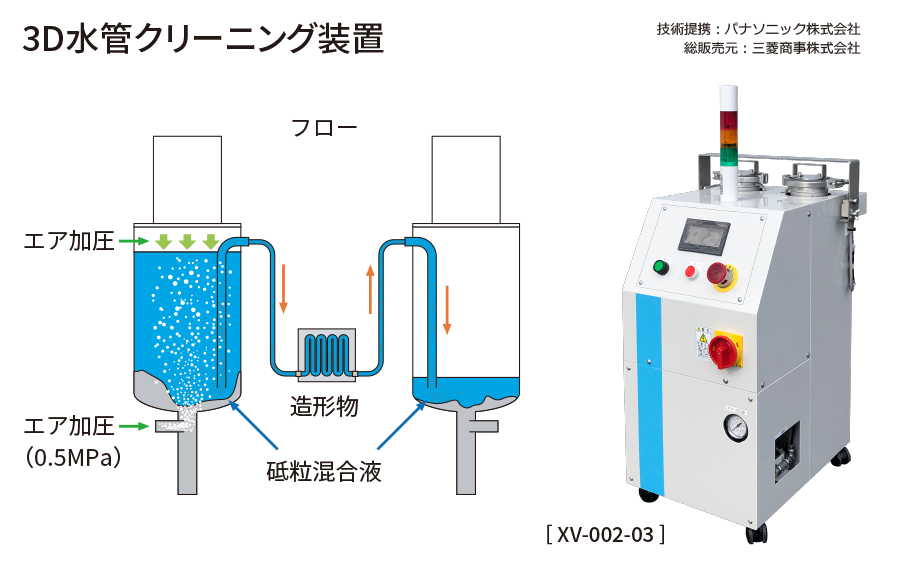

The water pipes of molds used in normal molding are designed to maintain a constant molding temperature, so in most cases the water pipes are placed halfway between the molding surface and the platen fixing surface. On the other hand, in "heat and cool molding", it is considered desirable for the temperature control water pipes to be located close to the molding surface in order to quickly raise and lower the temperature of the molding surface.

When installing a water pipe near the molding surface, if the product has a simple shape, it can be set with a straight water pipe. It is difficult to set up a water pipe.

That's where 3D metal printers come in. By sintering and layering metal powder with a laser, water pipes can be created in three dimensions, so even for molded products with complex shapes, water pipes can be placed along the molding surface of the mold. If you are mass-producing molded products using "Heat & Cool Molding," you should also consider using a dedicated 3D water pipe mold (note that a dedicated mold is essential for the steam type).

An important point to keep in mind when introducing "Heat & Cool Molding" is the management of the quality of the circulating water used for temperature control. If the water quality is poor, scale will form in the cooling water path and the temperature control efficiency will decrease, not only reducing the effectiveness of "Heat & Cool Molding", but also ultimately causing the water pipes to become clogged and the cooling water to stop flowing, leading to the breakdown of the temperature control equipment.

It can be said that maintaining the original condition of the water pipes is particularly important when using 3D water pipe molds. In the case of small molded products such as precision molded products, where the water pipes are thin and have complex shapes, they cannot be repaired if they become clogged. To maintain this original condition, regular maintenance using water pipe cleaning equipment is required.

For more information on water quality management, please refer to the column titled "Achieving stable production through water quality control of cooling towers and cooling water.."

Summary

"Heat & Cool Molding" not only reduces and improves the appearance defects of molded products, but also brings a higher level of molding quality that cannot be achieved with normal molding. Producing molded products that can be used without painting due to improved transferability has great benefits not only in terms of cost but also in terms of environmental consideration, and it is a technology that is expected to see further demand in the future. Improving the quality and value of molded products can be said to be an effort that leads to increasing the value of the molding factory.

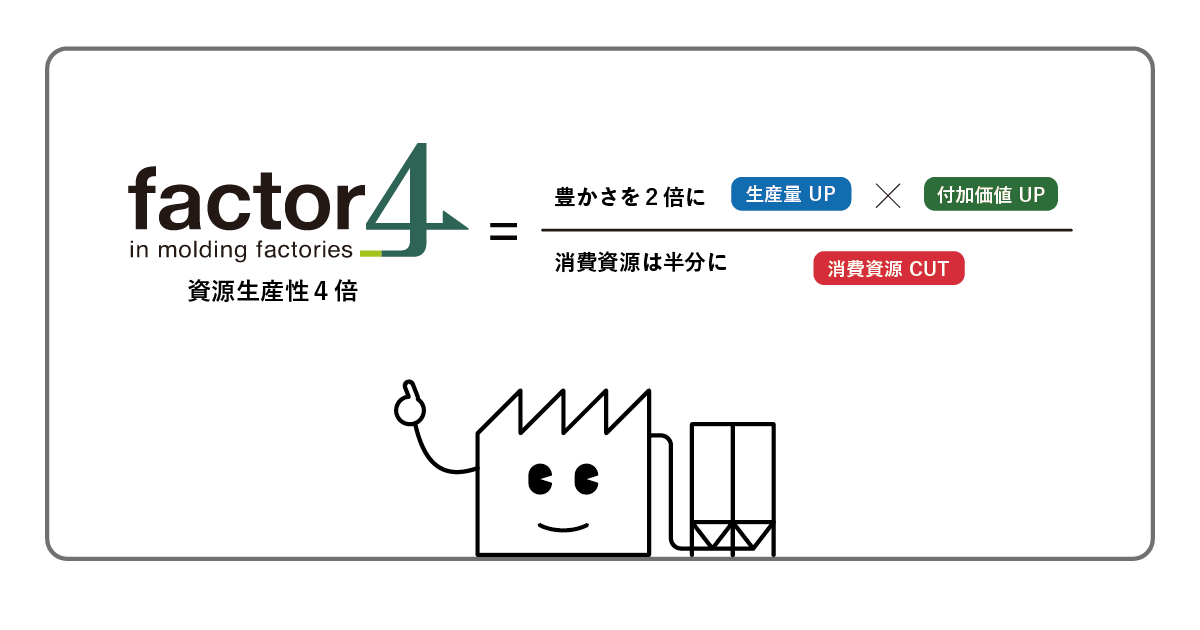

MATSUI 's mission is to "realize 'factor4' in molding factory", and we propose various solutions to improve the resource productivity of molding factory and improve the added value of molded products and molding factory. Please feel free to contact us.

CX Design Department Yasuhiko Iijima