特長

1. せん断発熱を抑えてガス・黄変・ヤケの対策に貢献します!

樹脂を加熱し過ぎることは、ガスやヤケといった成形不良に繋がるため、禁物とされています。

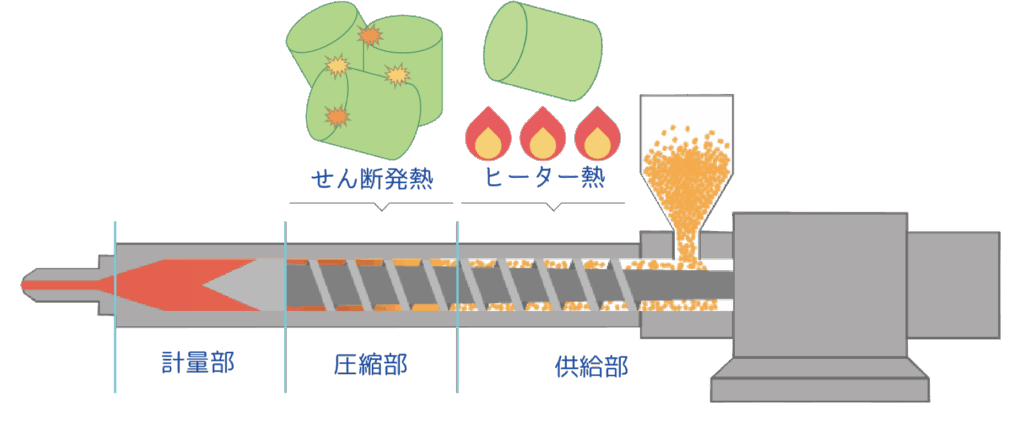

しかし、樹脂を成形機のバレル内で溶かす際、せん断発熱やヒーター熱は避けられません。

ヒーター熱は温度設定により調節可能ですが、せん断発熱はスクリュの回転によって起る物理現象であるため、いかに樹脂状態や充填状態を最適な状態に保つかが重要になってきます。

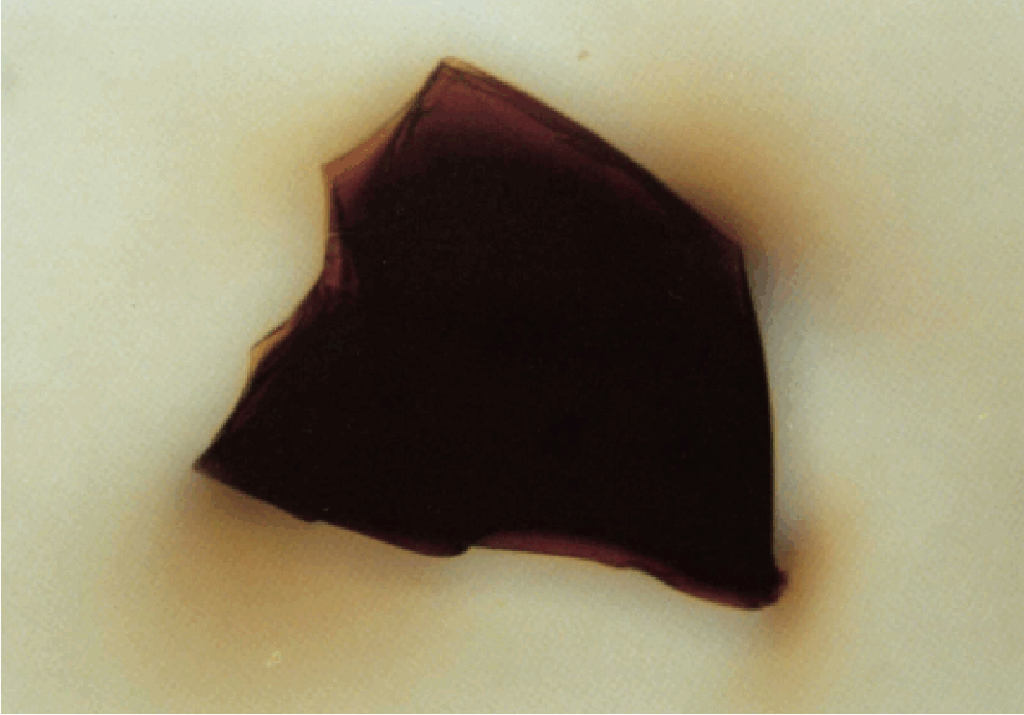

樹脂に過剰な熱が加わるとガス、黄変、ヤケが発生

せん断発熱は樹脂が引きちぎられたり、樹脂同士がこすれ合ったりすることで発生します。樹脂が硬いとスクリュの回転によってこれらの現象が起る際に必要となる力は大きくなるため、発熱も大きくなる傾向にあります。

したがって、樹脂を柔らかく保ち、発熱を抑えることが必要となります。

MIC はホッパー台専用の温度調節機で、通年で一定温調が可能です。樹脂の硬化を抑制し、せん断発熱の最小化に貢献します!

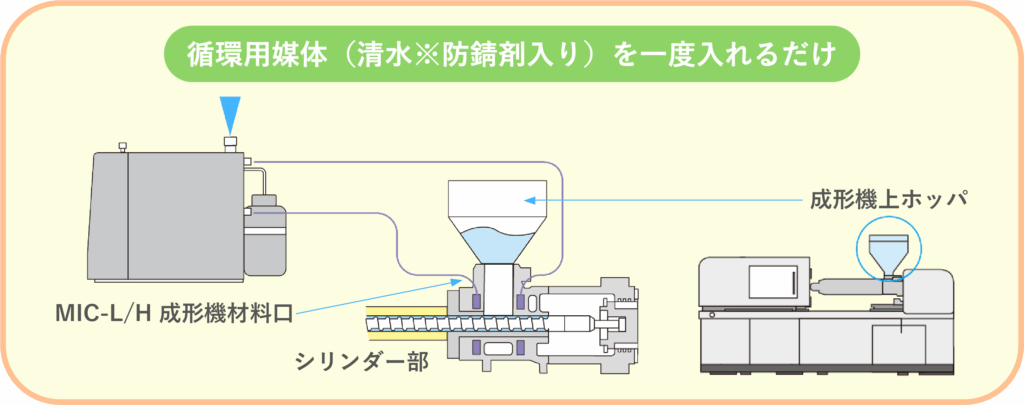

2. 特殊媒体により水管を清潔に保つため、スケールや錆の心配いらず!

装置内部のタンクに防錆剤入り清水を投入し密閉循環させています。そのため、ホッパ台の水管内で不純物が凝縮されることなく、金型入子などの被温調物をスケールの付着や錆の発生といった水質トラブルから守ることが可能です。

また、一次側の冷却水接続が不要なため、熱交換器はメンテナンスフリーです。管理に手間をかけることなく、材料口の細い冷却経路を熱の伝わりやすい環境で維持します。

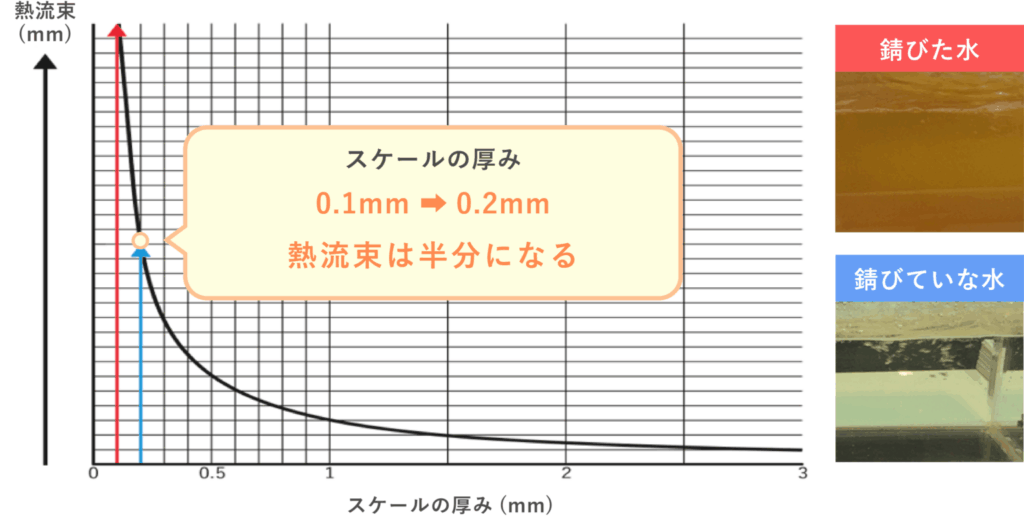

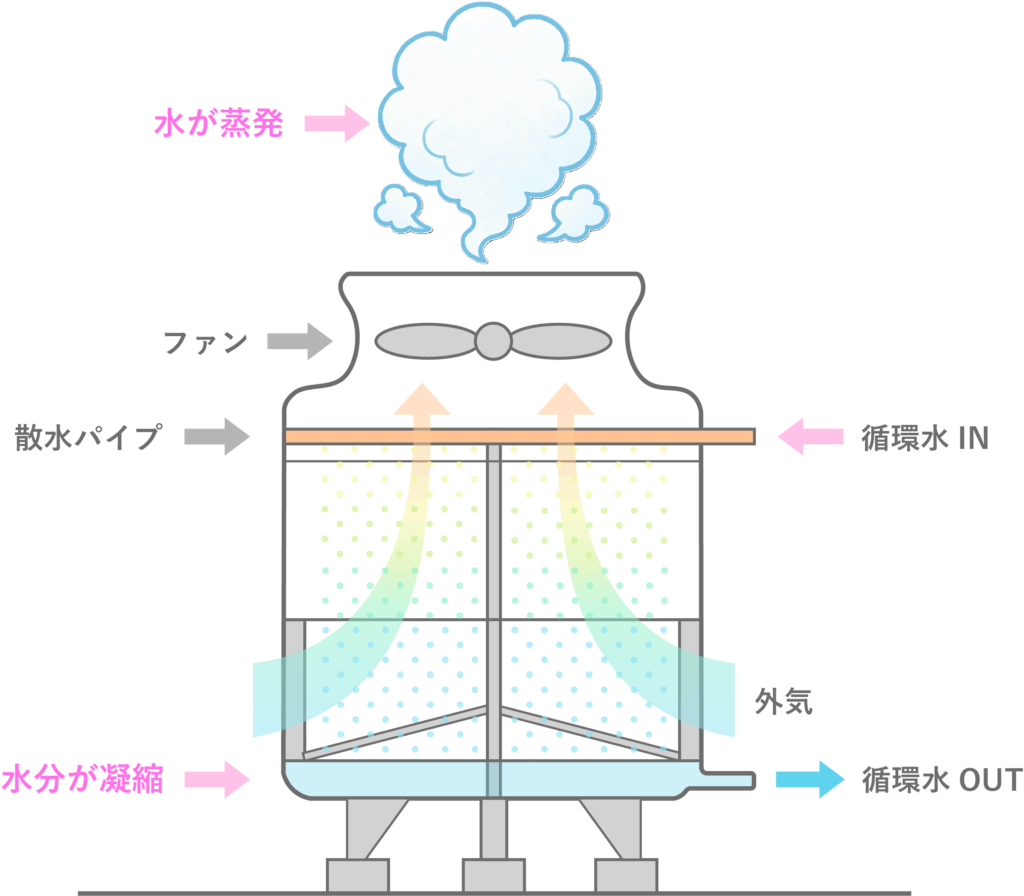

クーリングタワーを使用する場合、水環境をしっかり管理しなければ、水管にスケールが付着してしまいます。スケールが付着することで熱は伝わりにくくなるため、精度の良い温調は厳しくなります。

水の蒸発によってスケール成分は凝縮します。

3. 空冷式で、レイアウトは自由◎

MICはコンパクトな小型設計であり、尚且つ空冷の冷却方式です。そのため、一次供給水のレイアウトを気にすることなく、成形機のすぐそばに設置することが可能です。